"Can you communicate with buyers smoothly?"

"Is there a delay in delivery?"

"Why can't we obtain operation data and make use of it in factory management?"

"Do we have a stable relationship with buyers?"

SHIMA SEIKI combines various tools shown below to provide consulting and solutions optimized to each customer.

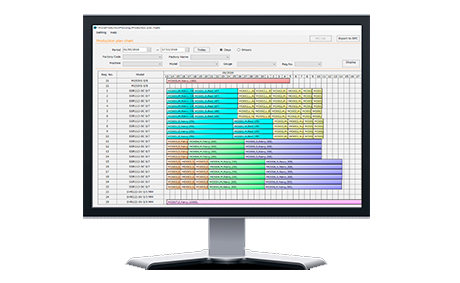

SPP (Shima Production Planning)

Create an efficient production plan

SPP makes it easy to create, adjust, and manage production planning for each knit factory using a Gantt chart. In addition to inputting necessary information on SPP, it can also be read directly from ERP, etc., reducing workload.

SPC (Shima Production Control)

Contribute to automation and time reduction

SPC transfers plans created on SPP to each flat knitting machine together with knitting data, saving time and preventing errors.

SPR3 (Shima Production Report3)

Visualize knit production

SPR3 collects real time data from flat knitting machines and can confirm actual progress for production planning. It can also analyze operator performance by shift as well as error information for each flat knitting machine.

SPR3 Dashboard Option

Visualize your production

Dashboard Option with newly improved database. With the alert function, you can quickly detect changes in the factory and analyze machine down time information to eliminate production bottlenecks.

Computerized flat knitting machine

Knitting machines connected online

By connecting the flat knitting machine online, it becomes possible to collect real time data and also to upgrade software versions remotely. Our knitting machines feature our own OS and realize high security.

SHIMA KnitManager Introductory Video

* Please note that the video uses the old name SHIMA KnitMAN, and now has been renamed to SHIMA KnitManager.

The contents of SHIMA KnitMAN and SHIMA KnitManager remains the same.

©2023 SHIMA SEIKI MFG., LTD.