Toward a new growth stage,

we will drive innovation in manufacturing and distribution.

Shima Seiki will continue developing new technologies

under our corporate motto “Ever Onward.”

The company aims to become an indispensable company

for society.

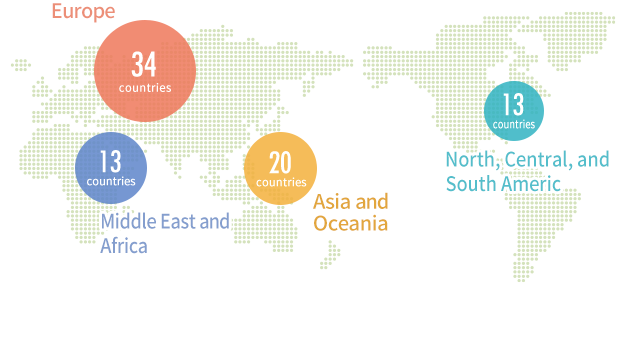

Overseas Market Potential

The company's overseas sales account for about 80% of its total sales, which involves Italy, the center of the fashion industry, China, the largest knit production site in the world, and Bangladesh and ASEAN countries that are expanding as new production bases. Centering on local companies in China, Hong Kong, Vietnam, Italy, the United Kingdom, and the United States, we have built service networks in each country to roll out our businesses and services globally.

-

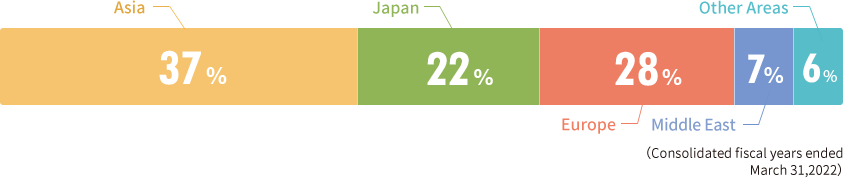

- Overseas sales ratio

-

- Number of bases

Total Fashion System

Shima Seiki provides design systems capable of handling every operation required in the apparel industry ranging from product planning and production management to sales promotion. They help reduce time and costs in every stage of the production process, such as planning and sample development, and thereby contribute significantly to improving the business efficiency of the apparel industry. Shima Seiki offers a total fashion system by drawing on its design system and brings change to the apparel industry by significantly streamlining planning and production processes. In recent years, the company has offered manufacturing applying the total fashion system to various fields other than apparel, such as interior, automotive, aerospace, and industrial materials.

* Our company likens the concept of All in One to a big tree. It symbolizes the message that, just like a big tree with many branches, we will provide products that can meet segmentalized manufacturing needs by using our design systems as a core.

* Our company likens the concept of All in One to a big tree. It symbolizes the message that, just like a big tree with many branches, we will provide products that can meet segmentalized manufacturing needs by using our design systems as a core.

Evolving Knit Products

Shima Seiki's proprietary WHOLEGARMENT widens the horizon of knit products via its three-dimensional formation, producing a wide range of items ranging from simple pullovers to unprecedented products.

Moreover, WHOLEGARMENT achieves unprecedented designs, beautiful silhouettes, high motion performance, high productivity, and production efficiency, as well as labor and resource saving. In short, it is the ultimate knitwear in all aspects.

WHOLEGARMENT technology has enabled the production of seamless tubes and other three-dimensional shapes, and has attracted much attention from various industries other than fashion, such as the interior, sports, healthcare, automotive, aerospace, and industrial materials.

Manufacturing Innovation

The WHOLEGARMENT flat knitting machine significantly contributes to the rationalization of production by eliminating the sewing stage, which requires the longest amount of time in the production process. Moreover, the virtual simulations of the design system have dramatically reduced the amount of time required to create samples, which used to be a bottleneck in the product planning process, achieving significant cost reduction. The WHOLEGARMENT machine combined with a design system has facilitated the transformation of the textile industry from a labor-intensive industry into a sensitivity and information-based industry that can manufacture products and create added value at consumption sites. In short, it achieves manufacturing that fully leverages resources and time. Moreover, the company also offers yarnbank, a website of yarn data opened with spinning companies. Through these efforts, the company will continue to support manufacturing in the fashion industry at every stage and thereby contribute to the vitalization of the industry.

page top

page top