- HOME

- About SHIMASEIKI

- HISTORY

Throughout our history,

we have cultivated our corporate spirit of

"If it can't be found anywhere, let's create it."

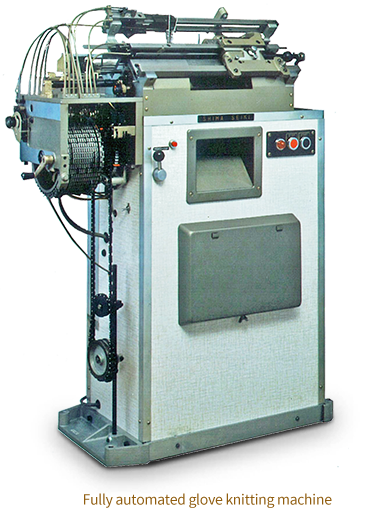

With the aim of meeting the challenge of an automated glove knitting machine, Masahiro Shima established the company in 1962 and successfully developed a fully automated glove knitting machine in 1964.

The company would later make inroads into the flat knitting machine business, which has become our core business.

Under our management principle of "Ever Onward ‐Limitless Progress," we continue our unwavering efforts to embrace the unknown and take on new challenges toward the innovation and development of new technologies.

- Corporate History

- History of Development

- 1962

-

- ・Masahiro Shima established SHIMA SEIKI MFG., LTD., in Tebira, Wakayama.

- 1964

-

- ・Successfully produces a fully automated glove knitting machine.

Starting Line

In 1964, the third year from the inception of the company, Masahiro Shima was working around the clock to develop a glove knitting machine but was running out of development funds and had debts of no less than 60 million yen. On December 24, 1964, the day before the maturity of a 600,000-yen note, he was on the verge of bankruptcy with no prospects for financing. However, on the evening of the same day, a miracle happened. A man, who was a total stranger, appeared and handed him some cash to honor the note. The man learned about Shima's desperate situation from an enterprise management consultant in Wakayama Prefecture and decided to help the young entrepreneur who was a stranger to him. For one week from that day, Shima, who barely escaped bankruptcy, worked day and night on the development of the machine and finally completed the world's first fully automated glove knitting machine on New Year's Eve. Early in the new year, Masahiro Shima held exhibitions and obtained orders for about 600 units, which marked the company's start as a fully automated glove knitting machine manufacturer.

- 1967

-

- ・Begins production of the world’s first fully automated collar knitting machine, the FAC,

and extends its business into the flat knitting machine industry.

- ・Begins production of the world’s first fully automated collar knitting machine, the FAC,

- 1968

-

- ・Owing to the increasing size of the company, the administrative offices and factory are moved to Sakata, Wakayama City, the present location.

- ・Developed the world's first fully automated semi-full fashion knitting machine, the SF.

- 1969

-

- ・Exhibited the SF machine at the Tokyo Harumi International Knitting Machinery Exhibition.

The company’s presence at this show ensures it a prominent place among manufacturers of flat knitting machines.

- ・Exhibited the SF machine at the Tokyo Harumi International Knitting Machinery Exhibition.

- 1970

-

- ・Developed the world’s first fully automated seamless glove knitting machine, the SFG.

- 1971

-

- ・Exhibited its products at the sixth International Textile Machinery (ITMA) Exhibition in Paris.

Upon receiving international acclaim, the company started exporting its products in earnest.

- ・Exhibited its products at the sixth International Textile Machinery (ITMA) Exhibition in Paris.

- 1974

-

- ・Introduced NC machine tools.

- 1975

-

- ・Developed a fully automated jacquard pattern glove knitting machine, the SJG.

- 1978

-

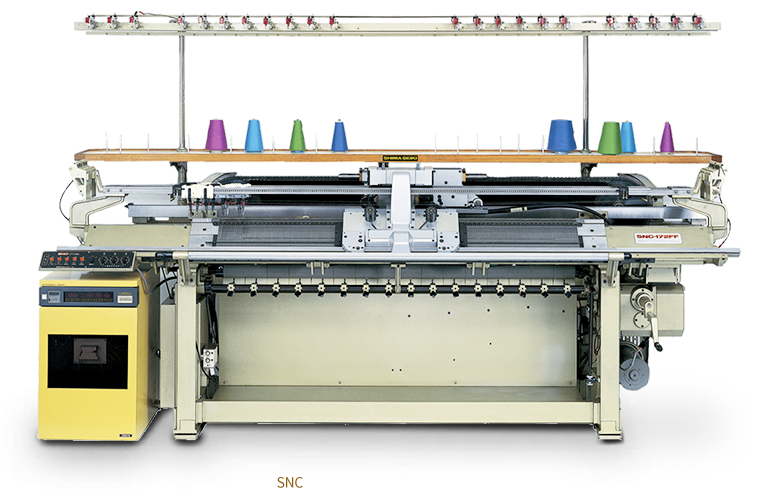

- ・Developed a computerized flat knitting machine, the SNC.

- ・Developed the TMS tape making system that regulates knit patterns.

- 1979

-

- ・Developed the famed SEC computerized flat knitting machine.

Turning Point

In 1974, because of the oil crisis that hit the Japanese economy in the previous year, our company's financial condition deteriorated. The company was at a crossroads because some financial institutions advised the company to reduce its workforce. Thinking about the situation for three days and three nights, Masahiro Shima decided to refuse the advice and decided to go in the opposite direction, that is, to introduce the NC machine tool. Believing that a significant change would take place in knit production from mass production to high-mix, low-volume production in the coming years, Masahiro Shima decided to introduce NC machine tools to develop a computerized flat knitting machine. This decision to introduce the cutting edge machine tool led to the in-house production of high-precision parts and the recruitment and development of employee who could operate the machine tool. It was Shima's brave decision made in the face of adversity that laid the groundwork for the company's future business development.

- 1981

-

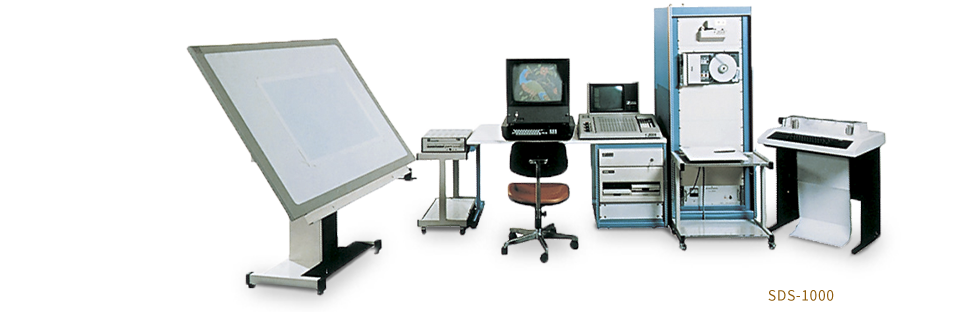

- ・Developed the SDS-1000 design system that utilized computer graphics for the first time.

- 1982

-

- ・Developed the SDS-500 series, the design system with in-house produced graphics units.

- 1985

-

- ・Established SHIMA SEIKI EUROPE LTD. in the U.K., the company’s first overseas subsidiary.

- ・Introduces the world’s first Digital Stitch Control System (DSCS) that supports knitting with a dimensional error of just ±1%.

- ・Developed the SDS-380 series of full-color computer graphics system, which is adopted in broadcasting and automotive industries, among others.

- 1986

-

- ・Established SHIMA SEIKI U.S.A. INC. in New Jersey.

- ・Developed the SDS-480 multi-design system featuring high-quality images and high-speed processing.

- 1988

-

- ・Developed the PGM-2 apparel CAD system for the creation of sewing patterns.

- ・Developed its long-anticipated next-generation computerized flat knitting machine, the SES series.

Computer Graphics

In order to give shape to consumer demand for a variety of fashion styles, Shima Seiki thought it indispensable to provide a design tool that worked in conjunction with flat knitting machines and set off on the in-house development of a design system. In 1979, two years before the SDS-1000 was developed, the company obtained information that NASA, which had launched the unmanned spacecraft Voyager, was going to sell three graphics boards that were used to create CG animation of Saturn and acquired one of them for 15 million yen. Shima Seiki began marketing the SDS-1000, which was developed when even the term "Computer Graphics" (CG) was not widely known, in earnest. Shima Seiki's CG technology would later earn a high reputation as a design tool in the television and other industries.

- 1990

-

- ・Company shares are publicly listed on the Second Section of the Osaka Securities Exchange.

- ・Developed the SuperMicro SDS for knitters.

- 1991

-

- ・Entered the CAD/CAM field with its P-CAM computerized fabric cutting machine.

- ・Developed the SES122-S computerized flat knitting machine with full-time spring-loaded sinker system.

- ・Developed the Hyper Paint 2 design system for other industries.

- 1992

-

- ・Company shares are publicly listed on the First Section of the Osaka Securities Exchange.

- 1993

-

- ・Developed the SES122RT computerized flat knitting machine with four needle beds.

- 1994

-

- ・Developed the SPL102CS computerized flat knitting machine with warp insertion capability.

- 1995

-

- ・Developed the SWG series, the world’s first commercially productive computerized WHOLEGARMENT knitting machines, at the 12th ITMA exhibition in Milan, Italy.

- 1996

-

- ・Company shares are publicly listed on the First Section of the Tokyo Stock Exchange.

- 1997

-

- ・Developed the SWG-FIRST computerized WHOLEGARMENT knitting machine featuring the newly developed SlideNeedle.

WHOLEGARMENT Computerized Flat Knitting Machine

In 1995, ITMA, which is held once every four years and was known as "the Olympics of textile machinery," was held in Milan, Italy. Our company exhibited the "SWG" WHOLEGARMENT computerized flat knitting machine. Once yarns are set in the SWG, it produces a knitted product without requiring any sewing in 30 minutes, and had such a great impact on visitors related to the textile industry from around the world that they called it "the magic of the Orient." At the time, the domestic knitting industry was facing a serious crisis because the industry had become hollowed out from the inexpensive imports from Asia. To squarely face and rise above the situation, our company strategically unveiled this computerized flat knitting machine at the 12th ITMA by moving up the initial plan of exhibiting it at the next exhibition. Later, the knitwear produced by the machine was named WHOLEGARMENT and the machine was dubbed the WHOLEGARMENT computerized flat knitting machine.

- 2000

-

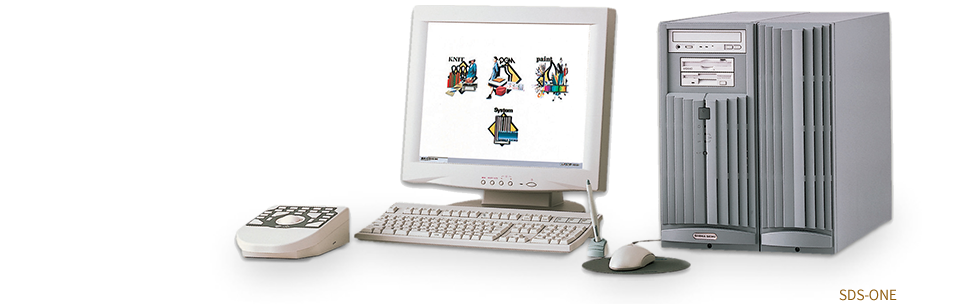

- ・Introduces its All-in-One design system, the SDS-ONE.

- 2002

-

- ・Releases its new SIP-100F printing system.

- 2003

-

- ・Developed the SWG021 WHOLEGARMENT flat knitting machine capable of producing small items and fashion accessories.

- 2005

-

- ・Developed the LAPIS hybrid warp/weft machine equipped with SlideNeedle.

- 2006

-

- ・Establishes SHIMA SEIKI WIN WIN LTD., in Hong Kong.

- ・Acquires 100% of the shares held by SHIMA-ORSI S.R.L. in Milan, Italy.

- ・Developed the SSG and SIG series of flat knitting machines with WideGauge technology.

- 2007

-

- ・Received the 53rd Okochi Memorial Foundation Grand Production Prize.

- ・Developed the MACH2 series, WHOLEGARMENT knitting machines with over twice the productivity of previous knitting machines.

- ・Developed the SDS-ONE APEX which expresses WHOLEGARMENT designs in 3D.

All in One

The conventional planning and production methods in the fashion industry had a structure featuring long lead times and the consequent high costs. However, amid ever diversifying consumer needs, new manufacturing methods were urgently needed. In such a context, Shima Seiki developed the SDS-ONE, which under the concept of "All in One," successfully integrated various functions, such as knitting CAD, and CG, in a single machine by adding a multi-window function. It achieved a significant reduction in pattern creation time in knit design. Moreover, by using high-definition virtual samples, both the time and cost involved in producing actual samples were also reduced, facilitating efficient production. This breakthrough product was soon adopted by leading apparel manufacturers in Italy, spreading our "TOTAL FASHION SYSTEM" around the world.

- 2010

-

- ・Developed the SSR series computerized flat knitting machines, which delivers outstanding cost performance.

- 2011

-

- ・Developed the SWG-FIRST154 computerized flat knitting machine, the world's first 21-gauge moldable flat knitting machine.

- ・Introduces the SDS-ONE APEX3 design system, which boasts greater speed and an improved simulation function.

- 2012

-

- ・Shima Seiki celebrated its 50th anniversary.

- ・Developed the P-CAM120C computerized cutting machine to support industrial materials including carbon fiber and composites.

- 2013

-

- ・Introduced the SRY123LP , a computerized flat knitting machine featuring newly developed loop presser beds.

- ・Introduces the SVR series computerized flat knitting machines.

- 2014

-

- ・Develops the SIP-160F3, an inkjet printing machine featuring a new ink circulation and degassing system.

- 2015

-

- ・Introduces the MACH2XS, the world’s first computerized WHOLEGARMENT knitting machine featuring movable full sinkers, which are mounted on 4 needle beds.

- 2016

-

- ・Started its "staf" web service.

- 2017

-

- ・Masahiro Shima became chairman and representateive director, and Mitsuhiro Shima became president and representative director of SHIMA SEIKI MFG., LTD.

Further Evolution

In 2015, which marked the 20th year since the introduction of the WHOLEGARMENT flat knitting machine, Shima Seiki succeeded in mounting fine movable sinkers on our proprietary four needle beds machine, leading to the development of the new MACH2XS. The MACH2XS, the crystallization of our technologies and efforts in resolving various developmental and production issues, has improved productivity, increased variations in three-dimensional patterns, and thereby enabled the production of even more attractive products. We believe that linking the MACH2XS to the cutting-edge SDS-ONE APEX3 design system will accelerate not only the mass production of knit items, but also production in consumption areas that can cater to particular local needs. Shima Seiki will continue to lead innovation in manufacturing.

- 2020

-

- ・Started the world’s first digital yarn sourcing website “yarnbank.”

- 2021

-

- ・Started subscription service for design

software “APEXFiz.” - ・Introduces the “SHIMANAVI” e-learning

system for SDS-ONE APEX series.

- ・Started subscription service for design

- 2022

-

- ・Develops a new flagship model

WHOLEGARMENT computerized knitting

machine “SWG-XR”. - ・Opens the “SHIMA Datamall” online service

that allows users to search,

browse, and

purchase various digital data that are

useful for the planning,

production, and

sales of fashion items.

- ・Develops a new flagship model