Glossary

ABC

APEXFiz

Software subscription service that fits diversifying work styles while retaining the strengths of the "SDS-ONE APEX" series. From planning and design to colorway examination, realistic fabric simulation, and 3D virtual sampling of products are also possible. The created virtual sample data can be converted as a production program by transferring it to a knit manufacturer. By digitally connecting planning and production and smoothing communication between the two, lead time is reduced and more accurate manufacturing is realized.

:

:- APEXFiz

Automatic fabric cutting machine

Our P-CAM series automatic cutting machines enable you to cut fabric and leather as well as carbon and glass fiber. They are used in a variety of areas including apparel, automotive, aircraft and industrial materials.

BtoB

The letter B implies Business and BtoB implies business-to-business transactions. A contrasting term is BtoC (C implies Consumer), which means transactions between enterprises and consumers. For example, the manufacturers of flat knitting machines can be referred to as they are executing BtoB businesses since they do not sell products to general consumers, but they sell products to manufacturers of knit products. On the other hand, the business styles of on-line shops, etc., that sell products directly to consumers are called BtoC.

CAD/CAM system

CAD stands for Computer Aided Design, meaning design by computer, while CAM stands for Computer Aided Manufacturing, meaning manufacture by computer. Shima Seiki offers apparel CAD systems to process the design of paper patterns, development of sizes, and efficient layouts and the P-CAM series, a computerized fabric cutting system for processing multi-ply or single-ply fabrics or leather hides. Currently, we offer our products not only to the apparel sector but also to areas involved in cutting of industrial materials, carbon fiber and other composite materials.

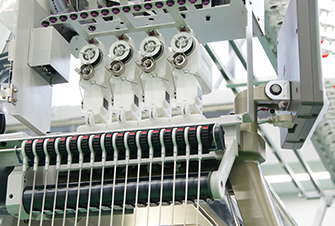

Computerized flat knitting machine

A computerized flat knitting machine is capable of computerized needle strokes, yarn selection and production control based on data stored in a computer, unlike manually operated knitting machines (called manual flat knitting machines) or mechanical knitting machines. Shima Seiki has a largest share in the world's computerized flat knitting machine market. On June, 2018, the total number of shipments have reached 200,000 units since the release of SNC, jacquard computerized flat knitting machine, in 1978.

Consumer market

This term refers to mature markets in developed countries that are shifting production overseas and undergoing increases in imports. In these markets, suppliers are required to produce high value-added products near consuming regions while delivering quick responses. The term typically refers to Europe, North America and Japan.

Conventional flat knitting machine

Conventional flat knitting machines are flat knitting machines other than WHOLEGARMENT flat knitting machines. Their primary markets are China, Hong Kong, South Asia and ASEAN countries. Conventional flat knitting machines require sewing and other works in downstream processes and suit labor-intensive production markets.

Cut and sewn

This is a generic term for knitwear and other garments that require higher levels of sewing skills for stitching knitted fabrics cut from paper stencils. This is one of the reasons why the textile industry is referred to as a labor-intensive industry.

DEF

Design centers

Design-related information outlets set up by Shima Seiki to popularize and promote fashion using WHOLEGARMENT and other new knitting technologies. In addition to the Total Design Center located in the headquarters, it is also deployed in Italy, China, the United States, the United Kingdom and Spain.

MILANO SHOWROOM (ITALY)

MILANO SHOWROOM (ITALY)

L.A. SHOWROOM (U.S.A)

L.A. SHOWROOM (U.S.A)

Ever Onward

Corporate motto of Shima Seiki. Under the persistent principles of corporate management, Shima Seiki is continuously working to develop new technologies and take on the challenges of entering uncharted territories.

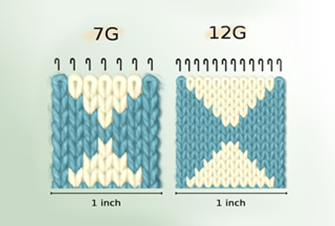

Fine gauge

Gauges for knitting in finer stitches (12 to 21 Gauge). Also called high gauges. Gauges for knitting in coarser stitches (3 to 5 Gauge) are called coarse or low gauges. Between fine and coarse gauges are called middle gauges (7 to 10 Gauge).

:

:- Gauge

Flat knitting machine

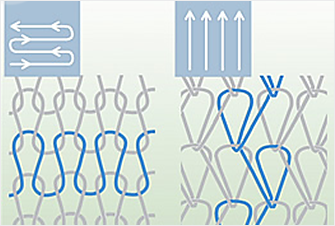

Knitted fabrics are either weft-knitted or warp-knitted. A flat knitting machine is a knitting machine used to knit fabrics consisting of chains of weft stitches.

Weft knitting

Warp knitting

GHI

Gauge

The unit representing the density of knitting machine needles, and the number of knitting needles per inch (approx. 2.54cm). The smaller the figure, the coarser the stitch, and vice versa.

7G and 12G stitches

7G and 12G stitches

Glove knitting machine

Machines for knitting gloves which Shima Seiki was originally founded. Shima Seiki developed the world's first automatic seamless glove knitting machine. Shima Seiki's glove knitting machines have a wide range of applications, including work gloves, gloves for precision machinery and coated gloves.

i-DSCS+DTC

This improved version of the world's first Digital Stich Control System (DSCS) that supports knitting with a dimensional error of just ±1%, can control yarn tension electronically in both feed and retrieval directions as necessary, and is critical to WHOLEGARMENT production.

i-Plating

It is a dedicated option for Shima Seiki's "SVR-SP" series computerized flat knitting machines equipped with loop pressers. Alternate yarns colors can be shown on the knit fabric for individual knitting needles, expanding pattern and design variety of knitwear significantly.

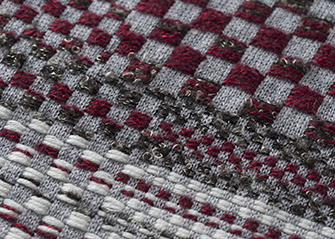

Inlay Fabric

Inlay fabric is a method that involves inlaying a weft into the knitted fabric base. Passing the weft between the loops of a knitted fabric produces an inlay fabric. Inserting a weft in this manner can help restrain the characteristic stretch of knitted fabric, allowing for the proposal of knitted fabrics that appear to be woven. This approach also facilitates the insertion of metallic and monofilament yarns or other specialty materials, which we believe should help in cultivating applications in other fields.

Intarsia

This knitting technique is used to incorporate inlays that are colored or patterned differently from that of the background into fabrics. This technique does not involve stitching yarns of the background color through the backing fabric and hence is most appropriate for thin knitwear of spring and summer. The well-known diamond checkerboard pattern of Scottish origin is called "argyle."

:

:- Jacquard

ITMA

ITMA is a comprehensive textile machinery trade fair held every four years in different cities in Europe. The ITMA trade fair will be held in Hanover, Germany, in 2027.

JKL

Jacquard

This term was originally used to refer to a type of figure loom invented by and named after French inventor Joseph Marie Jacquard. Today, knitting machines incorporating a variable or pattern knitting function are generically called "jacquard knitting machines" and garments knitted using jacquard knitting machines are called "jacquard." Jacquard knitting machines usually knit more than two colored yarns into various patterns.

:

:- Intarsia

Kaleido

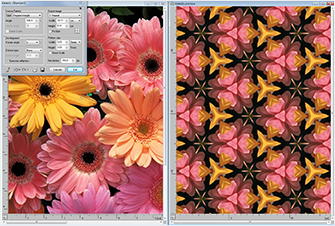

This is an image processing tool of the design system. It is capable of creating unlimited designs by developing part of a photo or illustration, in patterns like a kaleidoscope. Check patterns, stripe patterns, etc., can be created in a moment of time.

Original patterns (left side) and patterns produced by Kaleido (right side)

Original patterns (left side) and patterns produced by Kaleido (right side)

Knit programming

It means to create data for knitting products. When knitting products, it is necessary to develop instructions related to patterns and the knitting method so that machines can work correctly. The use of the knit CAD and knit paint software mounted on the SDS-ONE APEX series offered by Shima Seiki will enable equipment users to dramatically simplify complex programs based on a large database.

Knitting machine

A knitting machine is used to produce knitted fabrics. The three main types of knitting machine are flat knitting machines, which are the main products of the Company, circular knitting machines, and warp knitting machines.

Know-how

It means information or their accumulation such as technologies and expertise needed to develop and manufacture products. In order to sufficiently bring out high performance from products, Shima Seiki has been accumulating different expertise centered on the Total Design Center. Shima Seiki believes its strengths lie in its ability to offer not only hardware and software, but also expertise.

Knowledge-intensive industry

The industry is highly reliant on intellectual work in operating business. In order to meet diversifying needs, industrial activities have grown knowledge-intensive in the process of shifting to high-mix low-volume production and have become increasingly more sophisticated as a whole. For knit production, the WHOLEGARMENT flat knitting machines, which require fewer downstream operation processes, including cutting and sewing, can respond quickly to the high-mix low-volume and high-quality production. The strategy of Shima Seiki to promote marketing of the WHOLEGARMENT flat knitting machines is helping the knit industry convert from the labor-intensive processes to knowledge-intensive processes. This is also known as the "sensitivity/information industry" in Shima Seiki.

Labor-intensive industry

Such an industry that relies heavily on labor for business. The textile industry is said to be typically labor intensive. For knitted products, labor-intensive production, such as the sewing processes, is conducted mainly in South Asia and ASEAN countries.

LAPIS

LAPIS is a weft and warp knitting machine capable of producing colorful and original knitted garments that are impossible to produce conventionally. Up to 100 colors can be used. The name "LAPIS" comes from LAPIS LAZULI, Italian for "blue-colored gem."

Lead time

Time required from order receipt to delivery of finished products. In production, the period of time required from receipt of orders until completion of the manufacture of ordered products. It not only includes the time taken for processing but also the addition of time for waiting and transport.

MNO

MACH2XS

The WHOLEGARMENT knitting machine launched in 2015; 4 needle beds optimum for WHOLEGARMENT production are adopted; also has movable full sinkers device mounted. The remarkable speed and productivity make it possible to make beautiful, quality WHOLEGARMENT products more stably.

Market-in

A market-in approach is either a user-oriented approach for providing products and services that suit market needs or a customer-oriented approach taken by enterprises to business development from a customer's point of view. The antonym of "market-in" is "product-out."

MQC activities

Shima Seiki is pushing for quality improvement. The production division is taking the leadership in addressing this issue by applying the market-in (offerings driven by market needs) concept to both aspects of quality and cost.

Okochi Memorial Grand Production Prize

The Okochi Memorial Foundation presents awards for outstanding achievements in the field of industrial engineering and production technology. Among the awards from the Okochi Memorial Foundation, the most authoritative is the Okochi Memorial Grand Production Prize presented to the business organization that has made outstanding industrial achievements developed on its own.

In March 2007, Shima Seiki was awarded the 53rd Okochi Memorial Grand Production Prize by the Okochi Memorial Foundation in recognition of the development of advanced production systems to manufacture knit products by making use of the WHOLEGARMENT flat knitting machine and the Design System.

PQR

Pantone

This is the color sample book offered by Pantone, Inc., based in the United States. Pantone color books are used for choosing or designating colors in various business fields including printing, design, and fashion and are disseminated throughout the world. Our design system incorporates the Pantone Color Guides, thereby enabling smooth color communications.

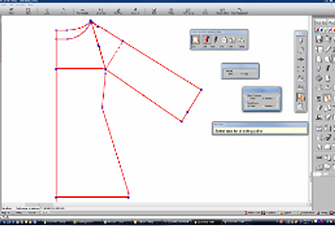

Pattern

This is used at the time of cutting the material and is referred to as the pattern created by plotting the shape of the required material. Generally, a pattern is used for a textile (woven fabric) in the fashion industry, but Shima Seiki applied it to the field of knit products. With our design system, the pattern for flat knitting can be created. Patternmaking plays an important role for high quality shaping and WHOLEGARMENT knitting. Our SDS-ONE APEX series are capable of not only creating high precision pattern, but also easily executing complicated knit programming since the knitting data can be converted from the pattern. The created pattern can be checked and edited through 3D simulations and the system is also utilized in the industrial material industry in addition to the fashion industry.

Production market

A production market is one with cheap labor for labor-intensive mass production and export. Typical markets of this type include South Asia, ASEAN countries and the Middle East.

Proper price

"Proper" means official, specific, or appropriate, and the proper price indicates regular priced-products with no discount. Apparel industry may refer to the ratio of products sold at the regular price during the season "proper digestibility."

Quick response (QR)

This term refers to corporate activities made to reduce product lead time and respond quickly to market needs. It also covers efforts made to facilitate such activities. A quick response allows sequential deployment of strong sellers into the market as needed and provides advantages in preventing lost sales due to lack of inventory, stock reductions, and logistics losses caused by returns.

STU

SDGs

The Sustainable Development Goals (SDGs) were adopted at the UN Sustainable Development Summit held in 2015 and will remain in place until 2030. They comprise 17 goals and 169 targets internationally aimed at the achievement of a sustainable world and call for the participation of both developing and advanced countries.

SDS-ONE APEX series

SDS-ONE APEX series are a design system offered by Shima Seiki with the functions of patterning, designing, and programming built into one unit under the development concept "All in One." The use of high-definition virtual samples and three-dimensional simulation enables the diversification of designs and reduced lead time and cost. The Company is expanding sales to industries other than apparel including textiles, interior, furniture and general merchandise.

Shima Cutting Solutions

By linking automatic cutting machines, automatic spreading machines, and automatic labeling devices, etc., we propose solutions for labor savings and automated pre-processing before cutting. Efficient workflow is also realized in cutting.

SHIMA Datamall

An online service that allows users to search, view, and purchase various digital data useful for planning, production, and sales of fashion items. By improving the operational efficiency of SDS-ONE APEX series, APEXFiz, and flat knitting machine users, we aim to provide stronger support for DX in manufacturing and facilitate a shift toward sustainable manufacturing

SHIMA HelpCenter

SHIMA HelpCenter is a customer support website that integrates Help, FAQ, Operation Manual, and Glossary functions for SHIMA SEIKI products.The cross-content keyword search and videos explanations provide easy-to-understand explanations of various product functions, leading to smart solutions to questions and problems during use.

SHIMA KnitManager

SHIMA KnitManager is production management software designed for the flat knitting factory.Visual confirmation of various information such as machine operation status and production progress is available for maximizing productivity and eliminating waste. Online monitoring service allows progress report to be checked via web application.

SHIMANAVI

E-learning system for the "SDS-ONE APEX" series. You can take classes at a time and pace that is convenient for you, and it matches new work styles such as telework. There are various courses according to customer needs, and multiple languages are supported.

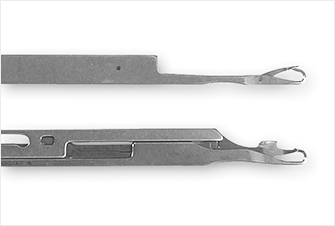

SlideNeedle

This is one of the knitting machine needles developed by Shima Seiki. This needle is of a design completely different from the conventional latch needles used for 150 years and is indispensable for four-bed WHOLEGARMENT flat knitting machines. SlideNeedle added six knitting techniques to the six conventional techniques and made it possible to produce knitted fabrics that are impossible to produce conventionally.

Latch needle (Top) and SlideNeedle (Bottom)

Latch needle (Top) and SlideNeedle (Bottom)

SRY

New type of flat knitting machine applying our original 4 needle beds; mounting "loop presser beds" on the top of needle beds and the same number of loop pressers as that of needles allows controlling pressdown of individual loops. This makes it possible to conduct inlay patters and fechage knitting stably, and largely expands the range of design.

Sustainability

By combining the WHOLEGARMENT flat knitting machine with the SDS-ONE APEX series, an apparel production system without the need for sample-making is realized. Shima Seiki advocates that truly sustainable manufacturing is achieved by providing consumers with what they want, when they want it.

SWG021N2/041N2/061N2/091N2 (WHOLEGARMENT-mini)

This is a WHOLEGARMENT flat knitting machine with a short knitting width of 20, 40, 60 or 90cm with the nickname of "WHOLEGARMENT-mini." Equipped with a SlideNeedle on the WHOLEGARMENT flat knitting machines makes it possible to produce small knit items, such as the gloves, socks, mufflers and supporters; knit wear designed for babies to toddlers and one-piece suits for late-teens, ladies’ spats, pairs of leggings, and tank tops.

Textile

It means fabrics and also means the overall textile products in broad terms. Textiles have warps and wefts that regularly cross over and are able to retain certain shapes with less shrinkage. Textiles have the features of mass production and high durability.

3D (three-dimensional) simulation

With our design system SDS-ONE APEX series, it is possible to set up the dimensions of human bodies, the color of the skin and hair, shapes thereof, etc., to create original 3D models. By fixing patterns in three dimensions on the model, considering the characteristics of the material and synthesizing the materials on it, real finished images, including the silhouette of the product, etc. can be examined by rotating the image 360 degrees.

Total Knitting System / Total Fashion System

Shima Seiki provides a lineup of products as Total Knitting System that supports the process starting from planning to production and sales promotion of knit products with our core design system SDS-ONE APEX series. In addition, we call the system whose applications are expanded throughout the apparel and fashion industries, in addition to the knitting industry, Total Fashion System. By disseminating such systems that achieve market-in, small-lot multiple-variety production and quick response and enable production of commercial products that respond to customer needs, we contribute to the vitalization of the fashion industry.

VWX

Virtual sample

Virtual samples are those generated by computers in virtual space with realistic images with visual textures that compare with those of final knitted products. Samples other than actual samples produced using knitting machines are all virtual samples. Samples printed on paper are also virtual samples. Conventionally, actual samples were prepared at product planning and investigation stages. Shima Seiki's SDS-ONE APEX series allows online simulation of finished products and contributes to remarkable reduction in investigation time and in costs.

Virtual sample made on the system

Virtual sample made on the system

Volume zone

This term is used to refer either to the most active and influential consumer segment in a market or to the price range of hottest sellers.

WHOLEGARMENT

Seam-free knitwear knitted three-dimensionally without the involvement of sewing together knitted fabrics cut from paper stencils or sewing together body parts and sleeves knitted separately. A high level of design and wear comfort are realized, and materials are least wasted due to the absence of cutting loss and seam allowance, which is environmentally friendly.

YZ

yarnbank

The website of yarn data opened with spinning companies. Registering yarn digital data provided by the companies on the website allows users to search for yarn appropriate as their preferred one and download the data for use as a virtual sample. Apparel companies can omit the efforts to digitalize data on a wide variety of yarns while spinning companies can use the website as a new promotional method for yarn products. The whole supply chain for spinning companies, apparel companies, and knitwear manufacturers can be mutually connected digitally via the yarnbank.