Current Conditions in the Fashion Industry

The textile industry is faced with many problems such as labor under harsh conditions and environmental pollution. SHIMA SEIKI has been proposing various measures as solutions to these problems.

SHIMA SEIKI carries out various methods of contributing to sustainability.

The textile industry is faced with many problems such as labor under harsh conditions and environmental pollution. SHIMA SEIKI has been proposing various measures as solutions to these problems.

Usually, knitwear is produced by knitting each part (front body, back body, and sleeves, etc.) separately and sewing them together. In contrast, SHIMA SEIKI’s WHOLEGARMENT knitwear is produced in one entire piece three-dimensionally directly on the knitting machine, preventing wasted material such as cut loss and seam allowance.

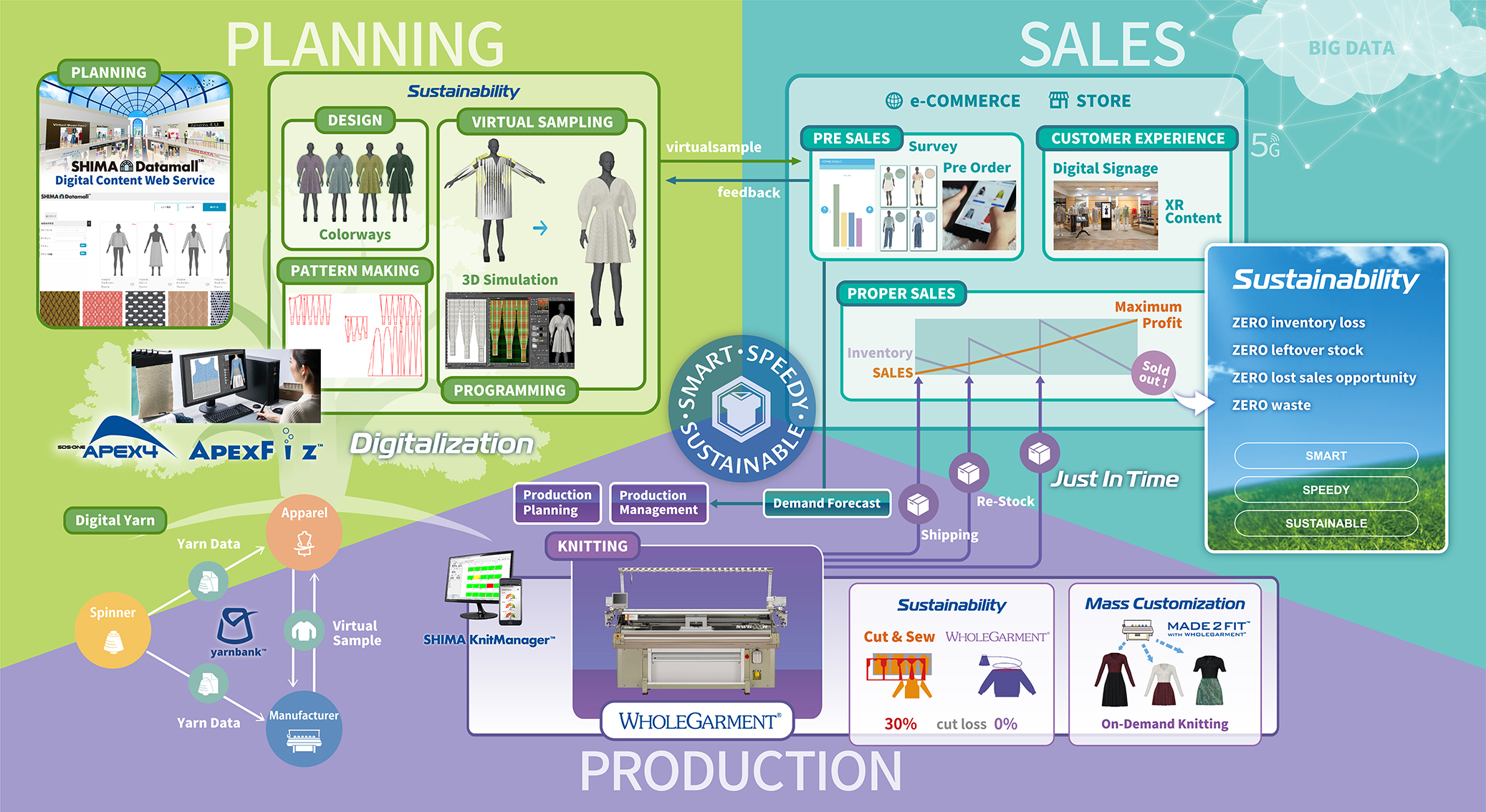

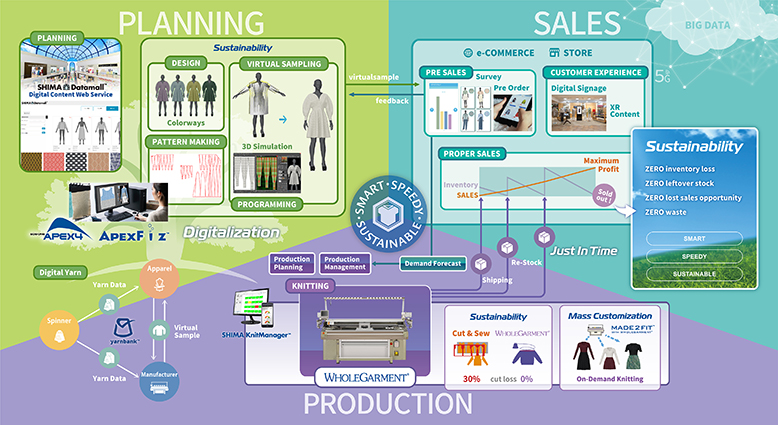

In combination with the SDS-ONE APEX series design system and software, the WHOLEGARMENT flat knitting machine realizes digitalization, mass customization, on-demand production, and just-in-time delivery. It is a truly sustainable system that provides consumers with what they really want when they really want it.

WHOLEGARMENT is made in one entire piece, so it is possible to unravel the yarn and reuse it to make something new. Items you've outgrown, or keepsake knits can be given new life. A new idea in recycling—only by WHOLEGARMENT.

Super realistic high-definition simulations created on SDS-ONE APEX series can be used effectively for prototyping of knitwear. Time, cost and materials are no longer required for producing prototype samples over and over again. Speedy planning, production, and sales using 3D virtual samples ultimately lead to zero inventory loss, zero leftovers, and zero waste.

SHIMA SEIKI's virtual samples begin with yarn simulation.

Place your finger or cursor over the image to activate the magnifying glass for a closer look.

3D virtual samples can be displayed in virtual space and can be used for presentations and retail promotion. Experience the future of online showrooms.

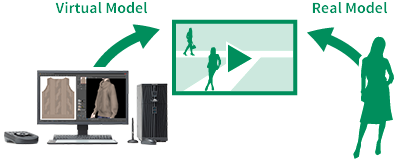

Virtual samples created on APEXFiz are combined with KDDI's XR mannequin technology to offer new customer experiences that will enable the use of virtual samples not only at the planning stage, but at the sales promotion stage as well.

By editing 3D virtual sample data, fashion shows can also be held in virtual space. The following video introduces SHIMA SEIKI's latest knit collection in a virtual fashion show format. Fashion shows can be held and viewed anywhere in the world.

SHIMA SEIKI’s manufacturing concept

SHIMA SEIKI promotes manufacturing that is beneficial to people and the earth, contributes to environmental conservation through the development and supply of “environmentally considerate products,” and upholds social responsibility as a global company. For this purpose, all business activities at our headquarters related to the design, manufacture and sales of our products have been granted ISO14001 certification by an accredited third party.

SHIMA SEIKI has incorporated global environmental protection into the SHIMA SEIKI Group Code of Conduct. We recognize the promotion of environmentally aware business activities and compliance with all environment-related laws and regulations as top management priorities.

The production division is promoting energy conservation, striving to reduce average annual energy consumption by 1% or more. We have introduced a large-scale solar-powered generation system at each factory building such as the Company's new FA Building No. 3 assembly plant for WHOLEGARMENT knitting machines. This step boosts the combined photovoltaic output of the SHIMA SEIKI Group's production plants to 1,550kW-one of the highest outputs for a Japanese private enterprise. We are thus effectively realizing a 10% reduction in power consumption by supporting natural energy resources.

Other SHIMA SEIKI energy-saving initiatives include the installation of thermal storage air-conditioners, the adoption of lighting systems using inverters and the reuse of dissipated heat from machine tools.

SHIMA SEIKI's efforts to promote greenery at its factories have yielded a 30% green area ratio for its 160,000 sq. meters of factory grounds. We have also planted some 12,000 trees, as part of our efforts to contribute to CO2 reduction. In October 2007, SHIMA SEIKI received the Outstanding Green Development Factory Award from the Minister of Economy, Trade and Industry (MITI) for its overall efforts to promote the greening of factories and its contributions to regional greening. In the future, SHIMA SEIKI will continue to promote and preserve the green development of its factories. Further, we will strive to improve such facilities as surrounding roadways, street lighting and pedestrian walkways.

We have also installed illuminations around the head office building, with additional crime-prevention benefits. Through such initiatives, we aim to contribute to local communities.