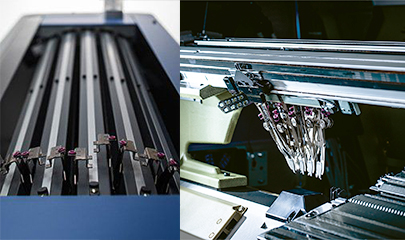

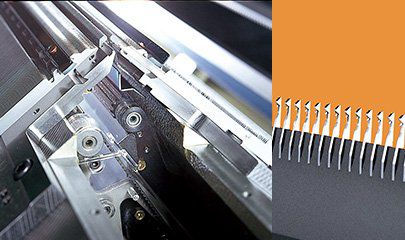

The Original SlideNeedle

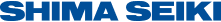

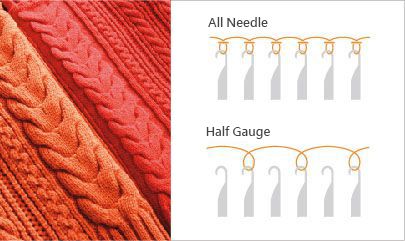

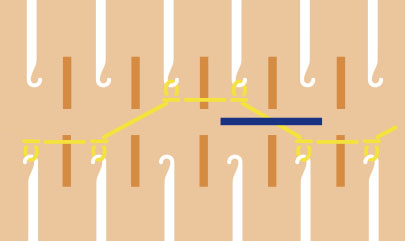

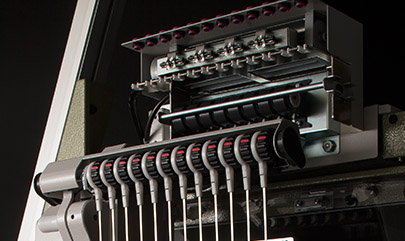

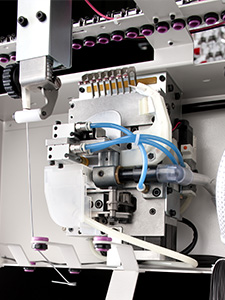

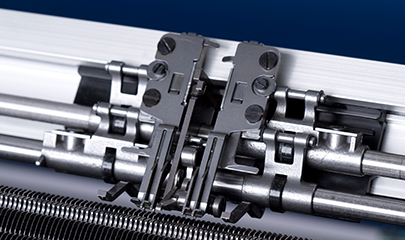

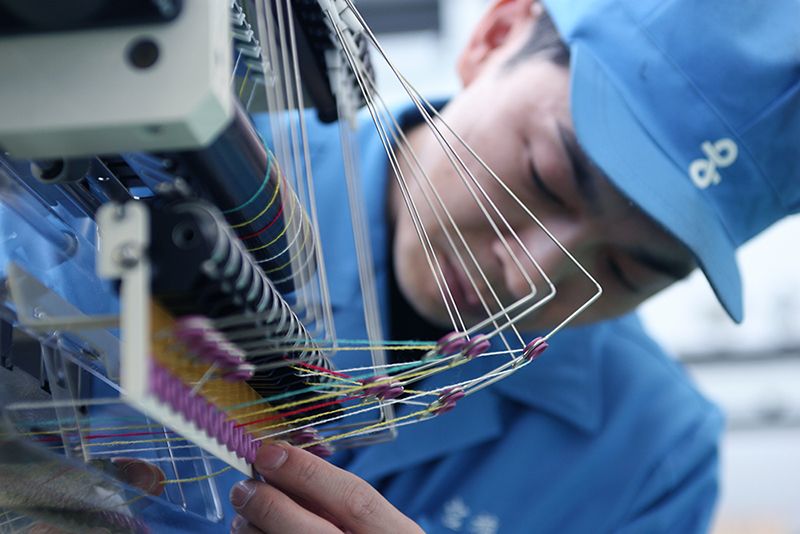

The SlideNeedle is the result of a thorough re-evaluation of the 150-year old design of the conventional latch needle. A flexible two-piece slider mechanism replaces the latch and offers knitting possibilities never imagined before. Using the slider mechanism for transfer effectively eliminates the transfer clip, allowing the SlideNeedle to be mounted in the center of the needle groove, thereby achieving perfectly symmetrical loop formation for knitting the highest possible quality fabrics.